Products | aeroFIX

aeroFIX Comments from user businesses

The use of aeroFIX is expanding to meet workplace needs.

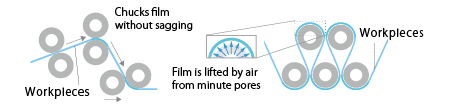

Achieved improved work efficiency and quality through stable workpiece lifting

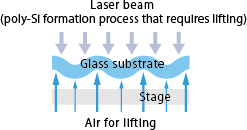

Application: Lifting

Use: Lifting stage of excimer laser annealing equipment for small and medium-size displays

Issue

- Because laser annealing involves directing the laser onto the workpiece, focusing is difficult.

- We wanted the laser to contact the workpiece when it is lifted, however it was not possible to securely hold the workpiece with conventional chucks.

Solution

- The introduction of aeroFIX produces precise, stable lifting that makes focusing easy.

- The fine pores deliver powerful partial chucking, resulting in a large improvement in work efficiency.

Evaluation

The strength of NanoTEM as a venture company is its ability to provide fine-tuned services, such as changing the composition of a product according to the application.

Because wax is no longer necessary, we were able to eliminate processes and succeeded in improving work efficiency.

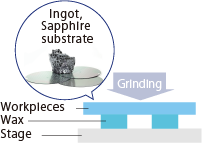

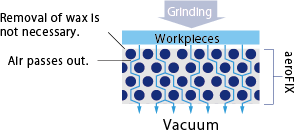

Application: Grinding

Use: Holding stage used in artificial sapphire grinding for LCD and LED products

Issue

- Wax is used to hold sapphire substrates in the process of grinding. However, the wax needs to be removed and cleaned which involves time and trouble.

Solution

- The introduction of aeroFIX achieved stable holding without the use of wax. Eliminating the wax-related work resulted in a large increase in work efficiency and cost savings.

Evaluation

There are many other interesting products in addition to aeroFIX. In particular, we are also interested in the grinding wheels.

Excellent technical capabilities helped us resolve all issues and turn our attention to new challenges.

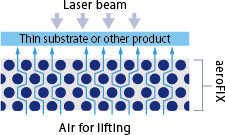

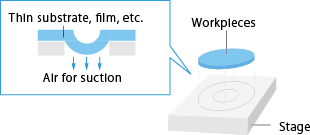

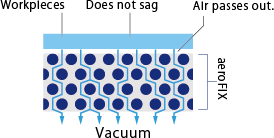

Application: Suction

Use: Film holding stage for next-generation displays (OLED)

Issue

- With conventional vacuum chucks, the film material would be sucked into the air holes on the suction surface, causing sagging and quality problems.

Solution

- The reasons for introducing aeroFIX were the following: (1) partial chucking without sagging, (2) capable of holding large areas, (3) produces no dust, (4) produces no static electricity, (5) high cost performance. It has performed extremely well in all these areas.

Evaluation

In addition to flat surface suction, there are many advanced technology products such as suction rollers and precision lifters that may be able to use in other processes.

Creative ideas with high future potential, and the possibility of collaborative technical development

Application: Suction, grinding

Use: Vacuum chucks for general grinding

Issue

- Our company develops and sells grinding equipment, however holding the workpieces during grinding has been a difficult issue for us, and we felt the need to develop products utilizing new technologies.

Solution

- We viewed the actual NanoTEM equipment and technologies, and were highly impressed with their technical capabilities and originality - more so than we expected, in fact.

- We felt that there is much future potential for the use of porous alumina and the technologies developed for grinding in technologies (for fixed abrasive grains) that are not currently in the mainstream.

Evaluation

We intend to work together, starting with joint technical development.