Precision Grinding and Polishing

Comparison of Grinding Methods

| Grinding Method | Through Feed Grinding | Infeed Grinding |

|---|---|---|

|

|

|

| Cutting Direction | Parallel to workpiece | Vertical to workpiece |

| Crack Formation | Parallel to workpiece (shallow) | Vertical to workpiece (deep) |

| Surface Quality | Small deformation | Large deformation |

| Material Service Quality | Good | Depends on cutting speed |

| Cut Speed | 0.1μm~10μm/min | 600μm/min |

| Cut Method | Place Z-axis on wafer side | Spindle moves vertically |

| Removal Rate mm3/s | Low | High |

| Feed Method | LM guide (air slider) Constant pressure feeding mechanism |

Ball screw feed mechanism |

| Process Accuracy | Less than 1μm/φ100mm | Less than 2μm/φ100mm |

| Chuck Type | Porous ceramic vacuum chuck | Porous ceramic vacuum chuck |

Optimal Grinding Mechanism According to Material

- To maintain dimensional accuracy

→ constant size mechanism - For better surface finish

→ constant pressure mechanism

- To find optimal processing condition

→ constant pressure mechanism - For knowing when to dress

→ constant pressure mechanism

- To achieve maximum grinding performance

→ constant pressure mechanism

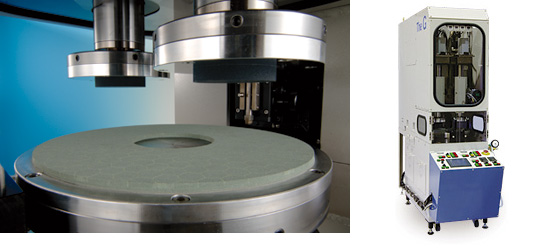

Constant Torque Infeed Grinder

Constant torque infeed grinder is a multi-purpose machine that grinds, laps and polishes, using NanoTEM's unique diamond grinding wheel. It requires minimum installation space and improves work efficiency, leading to high manufacturing performance.

Through Feed Surface Grinder with Constant Pressure

Suitable for cutting sapphire, ALTIC, alumina substrates. The newly developed constant pressure feed mechanism feeds the wheel with constant pressure deriving 100% of the grinding ability.

Product Information

The Grinder

Development of Innovative Technology

- Multi-purpose machine that grinds, laps and polishes

- Requires minimum installation space, improves work efficiency

- Water and air passing through the wheel controls the surface morphology of the workpiece.

Size:W500×L1800×H1850

The Grinder performs various processing which conventional equipment could not.

This improves the work efficiency of the next step, and leads to the precision of the product. It is especially suitable for grinding and polishing, hard and brittle materials such as sapphire, quartz glass and silicon.

"The Grinder" along with special diamond grinding wheel is the achievement of NanoTEM's next generation grinding technology, and will continue developing ideal manufacturing solutions for electronic component industries that keep growing and expanding.

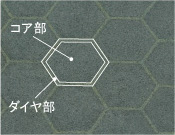

Image of water and air passing through precision diamond grinding wheel.

Specifications [The Grinder]

| Grinding Wheel Spindle | Rotation Speed | 5~1500min-1 | |

|---|---|---|---|

| Bearing | Ball Bearing | ||

| Motor | Belt Drive 3.7kW | ||

| Diameter | φ350mm (maximum) | ||

| Work axis | Effective Stroke (constant size/constant pressure feed type) |

80mm | |

| Resolution (constant size) | 0.1μm | ||

| Drive Type | Constant Size Type | Ball Screw Feed Mechanism 1μm/s | |

| Constant Torque Type | Air cylinder (push up) | ||

| Chuck | Vacuum Type | ||

| Maximum Work Diameter | φ125mm(5") | ||

| Rotation Speed | 5~200min-1 | ||

| Vacuum System | Water Seal Vacuum Pump | ||

| Vacuum Ejector | |||

| X-axis | Effective Stroke | 30mm | |

| Drive Type | Ball Screw Feed Mechanism | ||

| Feed Speed | 30reciproocation/min. | ||

| Facing Function | Effective Stroke | 150mm | |

| Drive Type | Ball Screw Feed Mechanism | ||

| Feed Speed | 3m/min. (maximum) | ||

| Machine Weight | 800kg | ||

| Clean Room | Classification | Class 10000 | |

Applications

●Blue light emitting diode ●Sapphire substrate ●Gallium arsenide ●Thin-film diamond